NPSH stands for Net Positive Suction Head. Why is it important in dosing pumps?

NPSH stands for Net Positive Suction Head. Why is it important in dosing pumps?

When choosing a dosing pump, an important technical factor to consider is NPSH (Net Positive Suction Head). Correctly understanding and applying NPSH helps prevent common issues such as cavitation, reduced pump performance, and costly damage to your dosing system.

In this blog, we explain what NPSH exactly is, how it works in dosing pumps, and how you can prevent cavitation in chemical dosing systems.

What does NPSH mean?

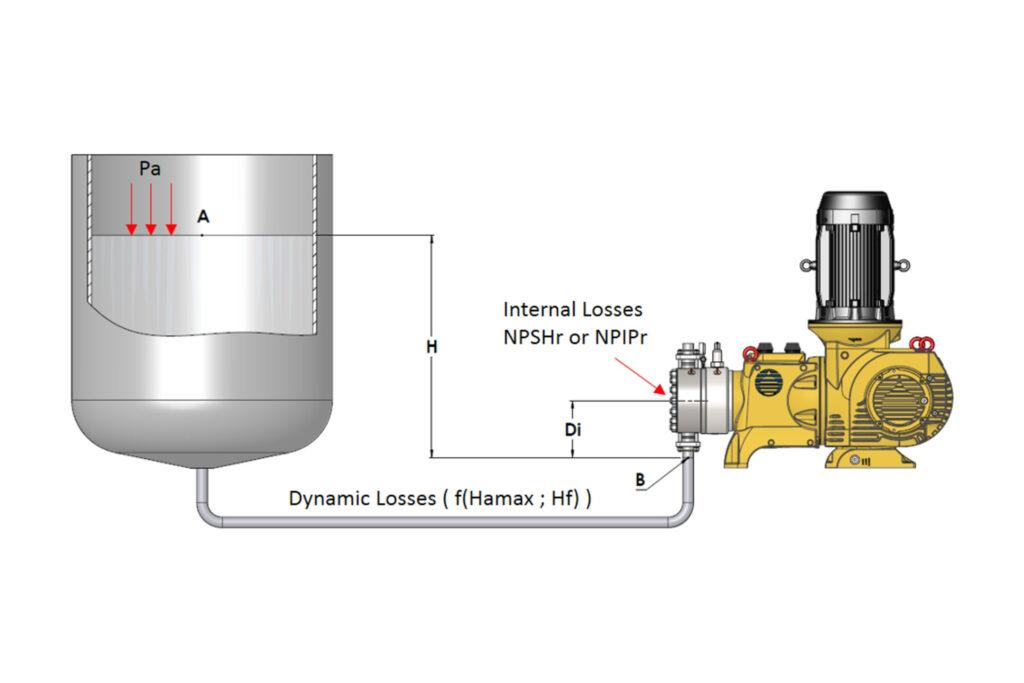

NPSH stands for Net Positive Suction Head and refers to the pressure available at the suction side of a pump, measured relative to the vapor pressure of the liquid. NPSH is crucial for preventing cavitation in dosing pumps.

There are two types of NPSH:

• NPSH Available (NPSHa): the pressure available in your system.

• NPSH Required (NPSHr): the minimum pressure a pump needs to operate properly (as specified by the manufacturer).

Important: If the NPSHa is lower than the NPSHr, cavitation will occur a damaging phenomenon where vapor bubbles form and collapse inside the pump.

Why is NPSH monitoring important in dosing pumps?

• Many liquids such as acids, bases, or solvents have a low vapor pressure, making them more susceptible to cavitation if the pressure at the pump suction side is insufficient.

• In dosing pumps, acceleration losses are significantly higher than in centrifugal pumps.

• If a dosing pump is placed above the liquid level or has a long/thin suction line, the NPSHa decreases significantly.

What are the consequences of insufficient NPSH?

• Cavitation: vapor bubbles collapse inside the pump, causing damage to the internal components.

• Higher maintenance costs: wear and tear on valves, diaphragms, or plungers.

• Reduced accuracy: dosing precision decreases due to air or vapor ingress.

• Reduced pump lifespan.

How do you prevent cavitation in dosing pumps?

1. Check the NPSHr of your dosing pump

You can find this value in the manufacturer’s datasheet. Make sure to maintain a margin of at least 2 meters of NPSHa above the NPSHr.

2. Calculate the NPSHa of your system

Take into account:

• The height difference between the liquid level and the pump

• Suction line (length, diameter, bends)

• Inlet pressure

• Temperature, vapor pressure, etc. of the liquid

3. Improve the installation if necessary

• Place the pump below the liquid level

• Reduce resistance in the suction line by using a shorter pipe or increasing the diameter

Example scenario: dosing pump for caustic soda

Suppose you are dosing caustic soda (NaOH) at 45 °C using a diaphragm dosing pump placed 1 meter above the tank level, with 3 meters of ½” suction line. Due to the low NPSHa and increased vapor pressure at this temperature, there is a real risk of cavitation unless you take active measures to prevent it.

Solution: shorten the suction line, increase the diameter to ¾”, and place the pump at floor level. This way, you increase the NPSHa and prevent damage.

Summary: NPSH in Relation to Dosing Pumps

Term Meaning

NPSHa Available suction pressure in the system

NPSHr Minimum pressure required by the dosing pump (from the manufacturer)

Cavitation Damaging effect of vapor bubbles in the pump

Solution Optimize the installation to ensure NPSHa > NPSHr

Conclusion

NPSH is a critical factor in correctly selecting and installing dosing pumps. By considering the balance between NPSHa and NPSHr, you can prevent cavitation, extend the lifespan of your pump, and ensure accurate and reliable dosing.

We’re happy to assist you with tailored advice, including NPSH calculations and installation optimization.

If you have any questions or need assistance with advice, please feel free to contact us.