All about industrial Mixers: How mixing works and why it’s so important

All About Industrial Mixers: How Mixing Works and Why It’s So Important

Whether it’s mixing water and chemicals, homogenizing liquids, or keeping solids suspended in a tank mixing is an essential process in countless industries. In this blog, we’ll take you into the world of industrial mixers: how they work, the different types available, and why good mixers can make all the difference for your production process.

What exactly is mixing?

Mixing is the process of combining two or more substances (often liquids or solids in a liquid) in a controlled manner to achieve a homogeneous or desired final product. In industrial applications, this often involves:

- Homogenization: Evenly distributing components.

- Dispersion: Finely distributing solids or gases within a liquid.

- Dissolving: Dissolving solids in a liquid.

- Suspension: Keeping solid particles suspended.

- Reaction Enhancement: Increasing the contact surface between substances to promote chemical reactions.

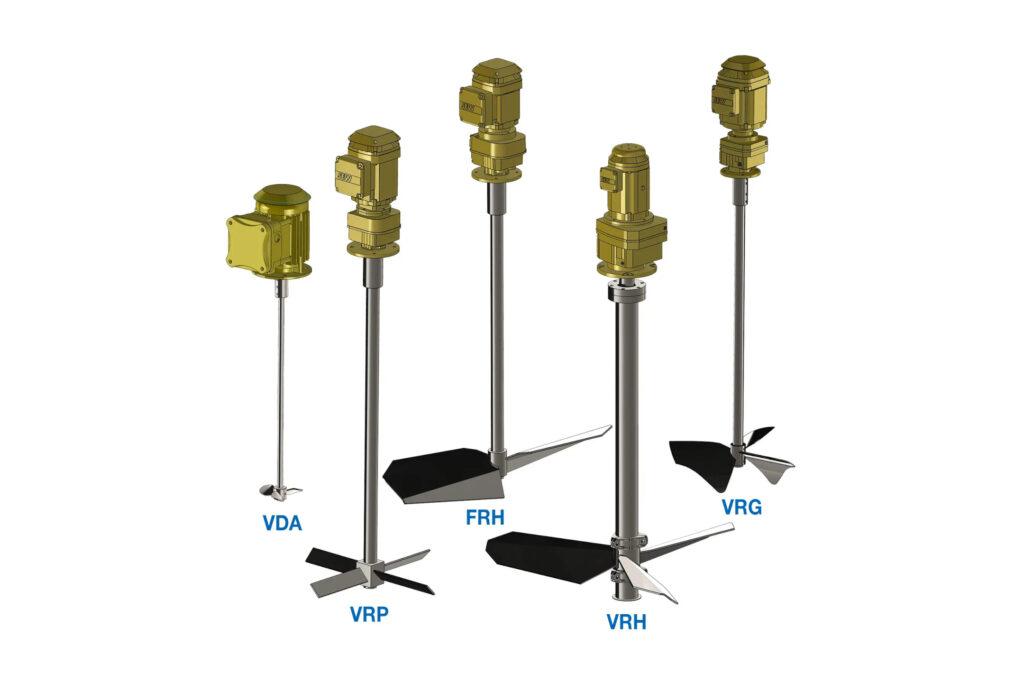

Types of Industrial Mixers

There are many different types of mixers, depending on the application and the properties of the substances being mixed. Here are the most common types:

1. Top-Entry Mixers

These are mounted on top of a tank and are suitable for both light and heavy mixing applications. They are commonly used in water treatment, food processing, pharmaceuticals, and chemical industries.

2. Side-Entry Mixers

Mounted on the side of large storage tanks, these mixers are energy-efficient and ideal for keeping large volumes of liquid in motion, such as in oil storage.

3. Bottom-Entry Mixers

Mounted at the bottom of a tank, these are often used when cleaning or space-saving is important, such as in the pharmaceutical industry.

4. Inline Mixers

In this type, substances are mixed outside the tank within a pipe system. They offer high speed and precise control, making them ideal for sensitive products or precision blends.

Key Factors in Mixing

Choosing the right mixer goes beyond just selecting the correct type. You need to consider:

- Viscosity of the liquid

- Tank size and shape

- Purpose of the mixing process (homogenizing, dissolving, etc.)

- Rotation speed and impeller design

- Energy consumption

- Maintenance and accessibility

Why Good Mixers Are Essential

A proper mixing system not only improves process quality but also ensures energy efficiency, reliability, and safety. Poorly mixed liquids can lead to product rejection, blockages, chemical instability, or costly downtime.

Milton Roy Mixers

Milton Roy has over 100 years of experience designing high-quality mixers and offers a wide range of mixers for applications in water treatment, chemical processing, oil & gas, and more. Their HELISEM® and HM series are known for energy-efficient performance, easy installation, and robust construction.

What sets Milton Roy apart is their focus on:

- Energy Efficiency: Advanced impellers (such as SABRE®) deliver significant savings compared to traditional mixers up to approximately 20% less energy consumption.

- Process Optimization: CFD analyses ensure minimal dead zones and optimal tank circulation.

- Ease of Maintenance: Robust mechanical seals, modular design, and some models are maintenance free under normal conditions.

- Wide Range: Standard Helisem mixers, modular HM mixers, side-entry mixers, and ROBIN® heavy-duty mixers.

Conclusion:

Whether you work in the food industry, chemical sector, water treatment, or energy production, mixing is a core process that determines the efficiency and quality of your final product. By investing in the right mixer tailored to your specific application you can prevent issues and boost productivity.

Milton Roy mixers offer a powerful range of solutions for a wide variety of industrial applications. Whether you need a reliable and fast solution for water treatment, robust storage mixing, or heavy-duty chemical processes, there is a suitable Milton Roy mixer for you.

If you are interested or have any questions, please feel free to contact us.

Or explore Milton Roy mixers, maintenance, and spare parts yourself.